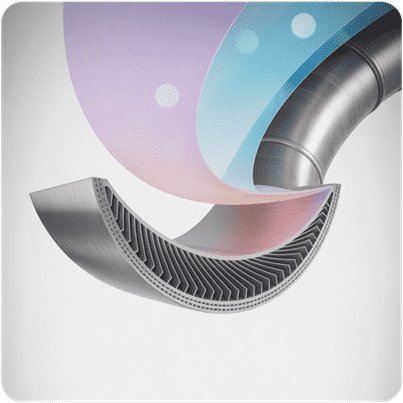

Casting Lightweight Aerospace Components

Advanced manufacturing techniques and simulation-driven approaches are revolutionizing how we create critical aerospace parts. From turbine blades to structural brackets, the demand for lighter, stronger components continues to push the boundaries of traditional casting methods.

The Critical Challenge of Weight vs. Performance

|

Aerospace casting faces a fundamental engineering paradox: components must be incredibly lightweight while maintaining exceptional strength and reliability. Every gram matters when fuel efficiency and payload capacity are at stake. Modern aircraft require parts that can withstand extreme temperatures, vibrations, and stress cycles while contributing minimal weight to the overall structure. This creates unique challenges for foundry professionals who must balance material properties, geometric complexity, and manufacturing feasibility. |

|

Advanced Materials Driving Innovation

Aluminum-Lithium Alloys

Offering 10-15% weight reduction compared to traditional aluminum alloys while maintaining superior strength-to-weight ratios. Critical for structural components in commercial aviation.

Titanium Casting

Essential for high-temperature applications like engine components. Requires precise control of cooling rates and atmosphere to prevent contamination and achieve desired microstructures.

Superalloy Development

Nickel-based superalloys enable operation at temperatures approaching 85% of their melting point, crucial for next-generation jet engines with improved efficiency.

FEA Simulation: The Digital Revolution

Finite Element Analysis has transformed aerospace casting from trial-and-error to predictive science. Modern simulation tools like PoligonCast enable engineers to visualize and optimize the entire casting process before pouring the first part.

Thermal-Mechanical Modeling

Predicts stress development during solidification and cooling, preventing hot tears and residual stress concentrations.

Solidification Simulation

Maps cooling rates and identifies potential porosity locations, enabling strategic feeding system design.

Flow Dynamics Analysis

Optimizes gating and runner systems to minimize turbulence and oxide formation during metal filling.

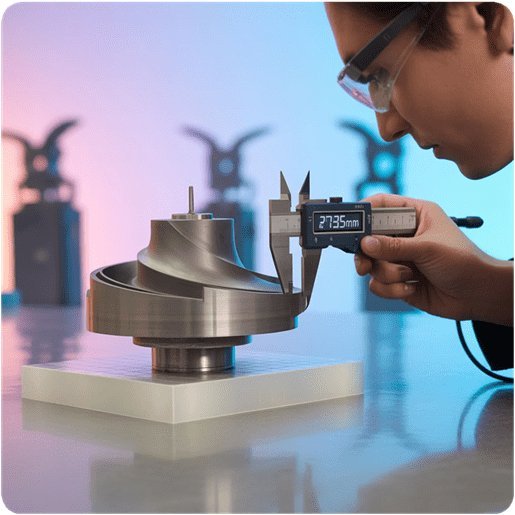

Real-World Manufacturing Challenges

|

|

Dimensional Precision Surface Quality Standards Defect Prevention |

Industry Trends Shaping the Future

Hybrid Manufacturing

Integration of additive manufacturing with traditional casting enables complex internal geometries impossible with conventional methods. 3D-printed sand cores create intricate cooling channels in turbine blades.

AI-Driven Process Control

Machine learning algorithms analyze real-time casting data to predict and prevent defects, optimizing parameters automatically based on historical performance patterns.

Sustainable Practices

Environmental regulations drive adoption of recyclable materials and energy-efficient melting technologies, reducing the carbon footprint of aerospace manufacturing.

Key Takeaways for Implementation

Invest in Predictive Simulation

Advanced FEA tools pay for themselves through reduced scrap rates and faster development cycles. Start with thermal-mechanical analysis for high-stress components.

Embrace Material Innovation

Stay current with emerging alloy developments and processing techniques. Partner with material suppliers to optimize casting parameters for new compositions.

Integrate Quality Systems

Implement real-time monitoring and feedback loops throughout the casting process. Use data analytics to identify optimization opportunities and prevent quality issues.

The future of aerospace casting lies in the intelligent application of simulation, materials science, and manufacturing innovation.

What's Your Reaction?