From CAD to Cast: Seamless Simulation Pipelines

Revolutionizing foundry productivity through integrated digital workflows that transform design concepts into precision castings with unprecedented efficiency and quality control.

The Digital Transformation Challenge

|

Traditional foundry operations face mounting pressure to reduce lead times, minimize defects, and optimize material usage. The disconnect between design intent and manufacturing reality has long plagued the industry, leading to costly iterations and production delays. Modern foundries are discovering that seamless simulation pipelines bridge this gap, enabling direct translation from CAD models to optimized casting processes. This integration eliminates manual data transfers, reduces human error, and accelerates time-to-market significantly. |

|

Core Simulation Technologies Driving Change

CFD Analysis

Computational Fluid Dynamics models metal flow, turbulence, and filling patterns to optimize gating systems and prevent defects like cold shuts and misruns.

Thermal Modeling

Heat transfer simulations predict solidification patterns, cooling rates, and thermal gradients to minimize porosity and optimize microstructure.

FEA Stress Prediction

Finite Element Analysis forecasts residual stresses, distortion, and cracking potential during cooling and solidification phases.

Solidification Modeling

Advanced algorithms predict grain structure, dendrite arm spacing, and phase transformations for superior mechanical properties.

The Seamless Pipeline Architecture

CAD Integration

Direct import of 3D models with automatic mesh generation and geometry optimization for simulation-ready formats.

Process Configuration

Automated setup of material properties, boundary conditions, and process parameters based on casting specifications.

Multi-Physics Simulation

Parallel processing of thermal, fluid, and mechanical analyses with real-time coupling for comprehensive predictions.

Design Optimization

AI-driven iterative improvements to gating, risering, and cooling systems based on simulation results.

Production Implementation

Direct export of optimized parameters to manufacturing execution systems and quality control protocols.

Quantifiable Benefits Transforming Operations

40%

Faster Time-to-Market

Reduced design iterations and optimized first-time-right casting success rates accelerate product launch timelines significantly.

25%

Material Savings

Optimized gating and risering systems minimize metal waste while ensuring complete filling and sound castings.

60%

Defect Reduction

Predictive modeling identifies potential issues before production, dramatically reducing scrap rates and rework costs.

30%

Energy Efficiency

Thermal optimization reduces furnace energy consumption and improves overall process sustainability metrics.

Industry Applications Driving Innovation

Aerospace & Defense

Critical components like turbine blades and structural castings require zero-defect production. Seamless simulation ensures compliance with AS9100 standards while optimizing complex geometries.

Automotive Evolution

Electric vehicle components demand new alloys and geometries. Integrated pipelines enable rapid prototyping of battery housings, motor components, and lightweight structures.

Energy & Semiconductor

Energy sector applications include wind turbine components and power generation equipment, where reliability and performance are paramount. The semiconductor industry leverages precision casting for specialized tooling and equipment components.

Implementation Best Practices

01. Data Standardization

Establish consistent CAD formats, material databases, and simulation templates across all projects to ensure pipeline compatibility.

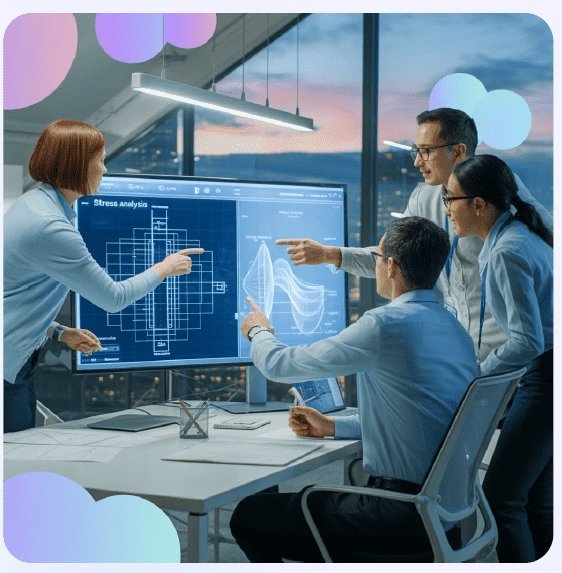

02. Team Integration

Foster collaboration between design engineers, simulation specialists, and production teams through shared platforms and regular reviews.

03. Validation Protocols

Implement rigorous correlation studies between simulation predictions and actual casting results to build confidence and accuracy.

04. Continuous Improvement

Leverage machine learning algorithms to refine models based on production data and emerging casting technologies.

Success requires commitment to change management, operator training, and gradual implementation across product lines. Start with pilot projects to demonstrate value before full-scale deployment.

The Future of Foundry Excellence

"Seamless simulation pipelines represent more than technological advancement — they're the foundation of next-generation foundry competitiveness."

The integration of CAD-to-cast workflows is becoming essential for foundries seeking sustainable growth. As Industry 4.0 technologies mature, the gap between simulation-enabled and traditional foundries will only widen.

Key Takeaway: Start your digital transformation journey today. Begin with pilot projects, invest in team training, and gradually expand simulation capabilities. The foundries that embrace seamless pipelines now will lead the industry tomorrow.

What's Your Reaction?